In the realm of advanced materials, refractory metals stand out for their exceptional resistance to heat and corrosion, making them indispensable in a wide array of industrial and technological applications. Among these esteemed elements, niobium (Nb), with its unique properties and versatile nature, occupies a prestigious position. This article delves into the world of high-quality, complete specifications of bright niobium wire, emphasizing its role within the broader category of refractory metals, niobium materials, and the myriad possibilities it unlocks.

Refractory Metals: The Backbone of High-Performance Applications

Refractory metals, including Tantalum, Tungsten, Molybdenum, and niobium, are renowned for their ability to thrive under extreme conditions. These metals are characterized by their high melting points, excellent strength at elevated temperatures, and remarkable corrosion resistance. Niobium, in particular, with its shimmering silvery-gray hue and a density close to that of steel, offers a combination of properties that make it an ideal candidate for specialized applications. Niobium: A Refractory Metal with Unparalleled Potential

Niobium's allure lies not just in its physical properties but also in its chemical versatility. It exhibits superconductivity at relatively high temperatures, making it crucial for the development of superconducting magnets and wires used in MRI machines and particle accelerators. Furthermore, niobium's ability to form alloys with other metals enhances the overall performance of these alloys, making them more durable and resilient.

Niobium Materials: Crafting the Future

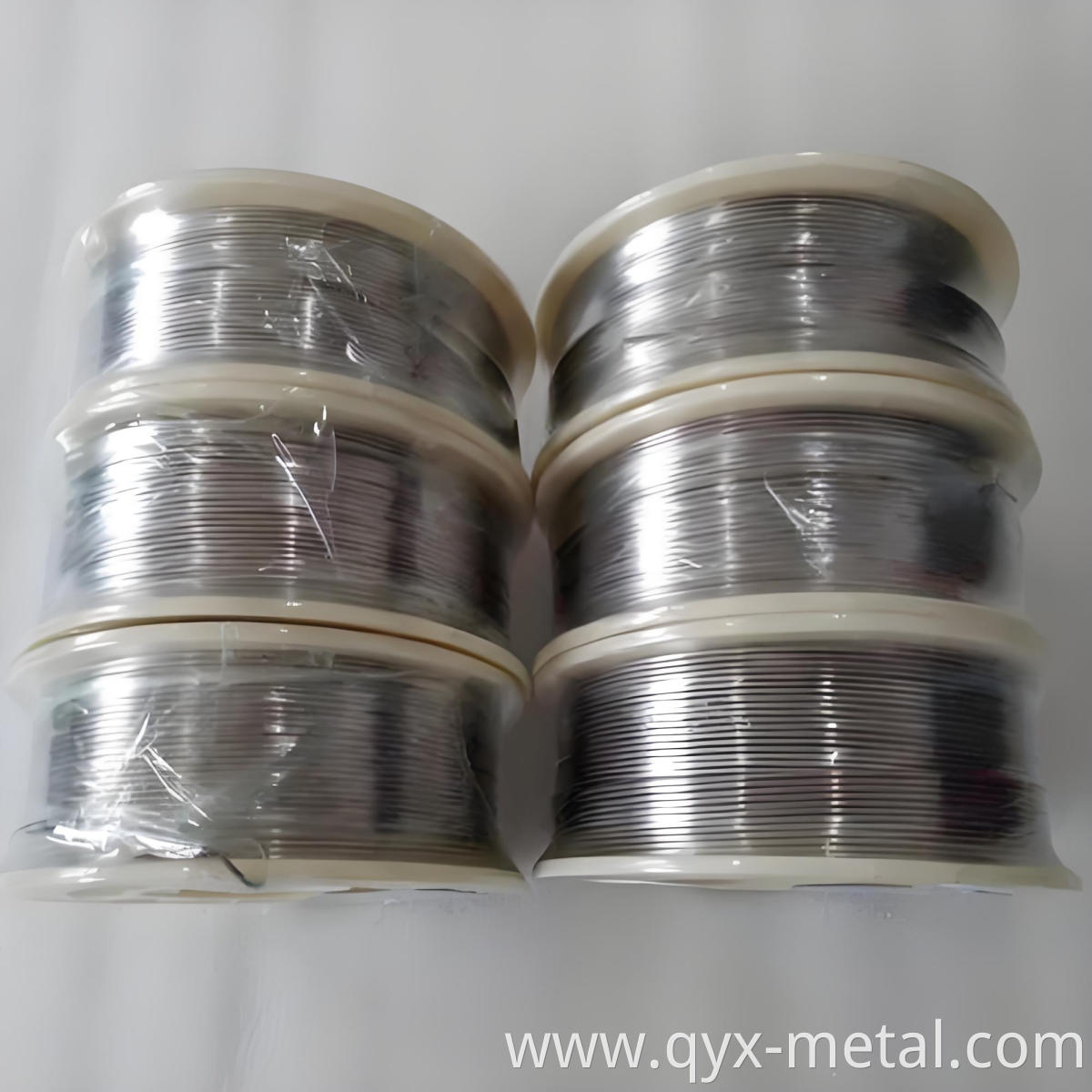

When it comes to niobium materials, the focus shifts to how this metal can be shaped and processed to meet specific needs. Bright niobium wire, in particular, represents the pinnacle of precision manufacturing. This type of wire undergoes rigorous processing to ensure a smooth, bright surface finish, free from defects, which is vital for applications requiring high electrical conductivity and corrosion resistance.

Applications Across Industries

The versatility of bright niobium wire spans multiple sectors:

Aerospace & Defense: Utilized in high-temperature components and superconducting magnets for advanced radar systems and propulsion technologies.

Medical Devices: Essential in the manufacture of MRI coils and other medical imaging equipment due to its superconducting properties.

Electronics & Semiconductors: Crucial for the production of capacitors, resistors, and other electronic components requiring high electrical conductivity.

Chemical Processing: Resistant to aggressive chemicals, making it ideal for use in reactors and heat exchangers.

Conclusion: Embracing the Future with Niobium

In conclusion, the realm of high-quality complete specifications of bright niobium wire opens up a world of possibilities within the refractory metals segment. By harnessing the unique attributes of niobium, we enable innovation and progress across diverse industries. From the depths of scientific research to the cutting edge of technological advancements, bright niobium wire stands as a testament to the power of refractory metals in shaping our future. As we continue to explore and refine the use of this remarkable element, the potential for groundbreaking discoveries and applications remains boundless.